Description

Standard Duty Air Caster Load Module System 17,000 LBS Capacity:

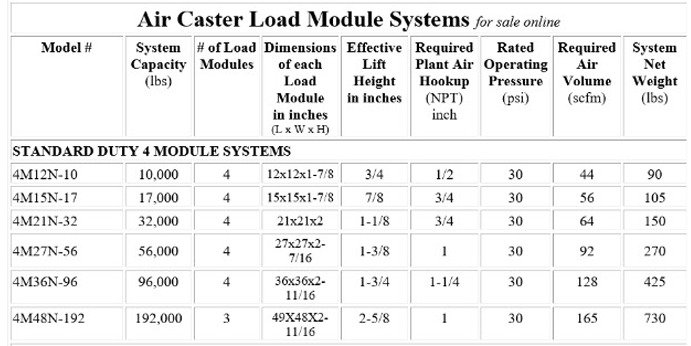

Our Load Rigging Systems & Modules utilize the efficiency of Fluid Film Technology to lift and move loads of any size, shape or weight up to 17,000 LBS with 4 module configurations.

Rigging systems are lightweight and easily positioned under a load. Unlike caster wheels, which resist changes in direction, rigging systems are truly omnidirectional, requiring no additional force to change direction. Control consoles provide individual pressure regulation to compensate for unequal load distribution. Because Rigging Modules float on a nearly frictionless film of air loads can often be moved manually, without the need for tow vehicles or winches. Air casters provide no perceptive shock or vibration when moving fragile or sensitive machines.

Rigging systems are available to move anything that isn’t anchored down. The rigging system module’s thin profile allows ASE System’s products to be easily inserted under most equipment, eliminating the need for a separate jacking system, as well as providing vertical lift when inflated.

Revolutionizing Medium Load Handling with Air Caster Technology

The Standard Duty Air Caster Load Module System 17,000 LBS Capacity is engineered to efficiently and safely move medium-weight loads across various industrial settings. Utilizing Fluid Film Technology, this system allows for the effortless movement of equipment and machinery, ensuring operational efficiency and safety.

Standard Duty Air Caster Load Module System 17,000 LBS Capacity Key Features and Specifications :

-

System Capacity: 17,000 lbs

-

Number of Load Modules: 4

-

Module Dimensions: 15″ x 15″ x 1-13/16″

-

Effective Lift Height: 7/8″

-

Required Plant Air Hookup: 3/4″ NPT

-

Rated Operating Pressure: 30 psi

-

Required Air Volume: 56 scfm

-

System Net Weight: 123 lbs

These specifications highlight the system’s robust design and its capability to handle various tasks with precision and ease.

Advantages of the Standard Duty Air Caster Load Module System 17,000 LBS Capacity

Omnidirectional Movement

Unlike traditional caster wheels, which can resist changes in direction, the Standard Duty Air Caster Load Module System 17,000 LBS Capacity offers true omnidirectional movement. This feature allows for seamless navigation of loads in any direction without additional force, enhancing operational efficiency.

Reduced Floor Damage

The system’s design ensures even load distribution, minimizing stress on flooring surfaces. This reduces the risk of floor damage, making it suitable for facilities with sensitive flooring.

Enhanced Safety

By allowing loads to float on a thin film of air, the system reduces the physical strain on operators. This not only improves safety but also decreases the likelihood of workplace injuries.

Cost-Effective Operations

The air caster system operates using standard industrial plant air, eliminating the need for expensive lifting equipment. Its low maintenance requirements further contribute to cost savings over time.

Applications Across Industries

The versatility of the Standard Duty Air Caster Load Module System 17,000 LBS Capacity makes it suitable for a wide range of industries, including:

-

Manufacturing: For moving machinery and equipment within production facilities.

-

Aerospace: Handling delicate components and assemblies without causing damage.

-

Automotive: Transporting parts and assemblies efficiently.

-

Electronics: Moving sensitive equipment with precision and care.

-

Healthcare: Relocating medical equipment safely.

Operational Workflow

Step 1: Preparation

Before inflation, the load rests securely on landing pads, protecting the air caster’s torus bag from damage.

Step 2: Inflation

Applying air inflates the torus bag, creating a seal against the floor and raising the load.

Step 3: Movement

Once the internal pressure offsets the load’s weight, air escapes evenly between the torus bag and the floor, allowing the load to float on a thin cushion of air, typically 0.003 to 0.005 inches thick.

System Components

Each Standard Duty Air Caster Load Module System 17,000 LBS Capacity includes:

-

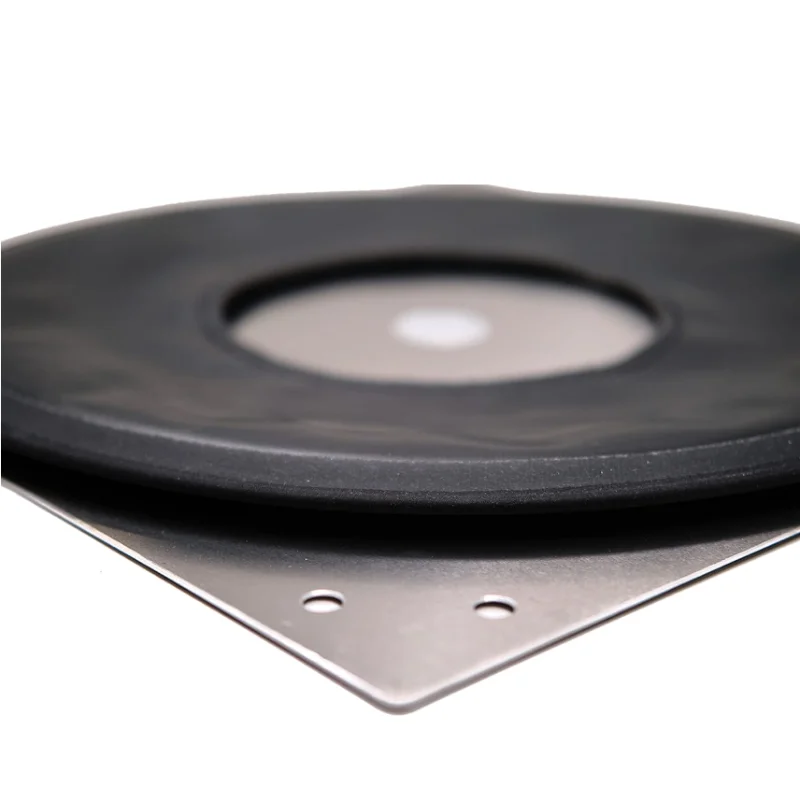

(4) air caster load modules with neoprene elements

-

(4) interconnect hoses with fittings

-

(1) 4-station control console with on/off ball-valve

-

(1) 35-foot air supply hose with fittings

These components work in unison to ensure smooth and efficient load movement.

Optional Accessories

To enhance the functionality of the Standard Duty Air Caster Load Module System 17,000 LBS Capacity, ASE Systems offers a range of optional accessories:

-

Power Drives: Steerable, air-motor, and battery-powered drive units for moving heavier loads with optional pendant controllers.

-

Air Jacks: Inflatable jacks designed for industrial lifting applications, capable of being inserted into spaces as low as one inch.

-

Guide Wheel Units: Assist in guiding loads during movement for increased control.

-

Hose Reel Systems: Facilitate the management and storage of air supply hoses.

These accessories can be integrated to tailor the system to specific operational needs.

Conclusion

The Standard Duty Air Caster Load Module System 17,000 LBS Capacity stands as a testament to ASE Systems’ commitment to innovation and efficiency in material handling solutions. Its advanced features, combined with optional accessories, provide a comprehensive solution for industries seeking to enhance their load movement capabilities.