Description

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity utilize the efficiency of Fluid Film Technology to lift and move loads of any size, shape or weight up to 360,000 LBS with 4 module configurations.

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity are lightweight and easily positioned under a load. Unlike caster wheels, which resist changes in direction, rigging systems are truly omnidirectional, requiring no additional force to change direction. Control consoles provide individual pressure regulation to compensate for unequal load distribution. Because Rigging Modules float on a nearly frictionless film of air loads can often be moved manually, without the need for tow vehicles or winches. Air casters provide no perceptive shock or vibration when moving fragile or sensitive machines.

Rigging systems are available to move anything that isn’t anchored down. The rigging system module’s thin profile allows ASE System’s products to be easily inserted under most equipment, eliminating the need for a separate jacking system, as well as providing vertical lift when inflated.

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity Product Overview:

System Capacity: Up to 64,000 lbs (29,030 kg) with a 4-module configuration

Our Load Rigging Systems utilize the efficiency of Fluid Film Technology to lift and move loads of various sizes, shapes, and weights. By harnessing compressed air, these systems create a thin, frictionless film that allows heavy loads to “float,” facilitating smooth and omnidirectional movement.

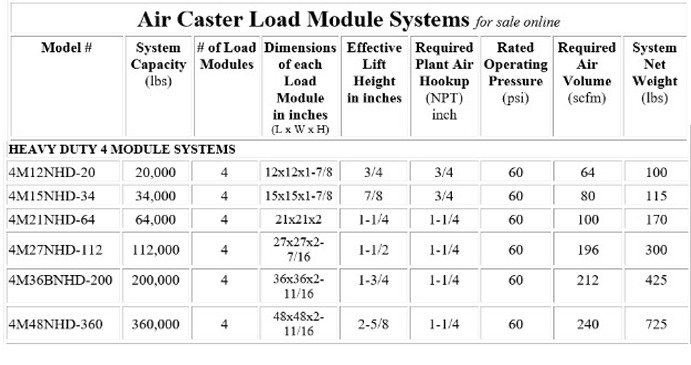

Technical Specifications

-

Load Capacity: Up to 64,000 lbs with a 4-module setup

-

Module Dimensions: Varies based on model; designed for low-profile insertion

-

Effective Lift Height: Approximately 1.5 inches (38 mm)

-

Air Pressure Requirement: Typically 60 PSI (4.14 bar)

-

Air Volume Requirement: Approximately 196 SCFM (5.55 m³/min)

Note: For optimal performance, especially on uneven or porous surfaces, it’s recommended to have an air supply capacity that is 30% higher than the minimum requirement.

System Components

Each Load Rigging System includes:

-

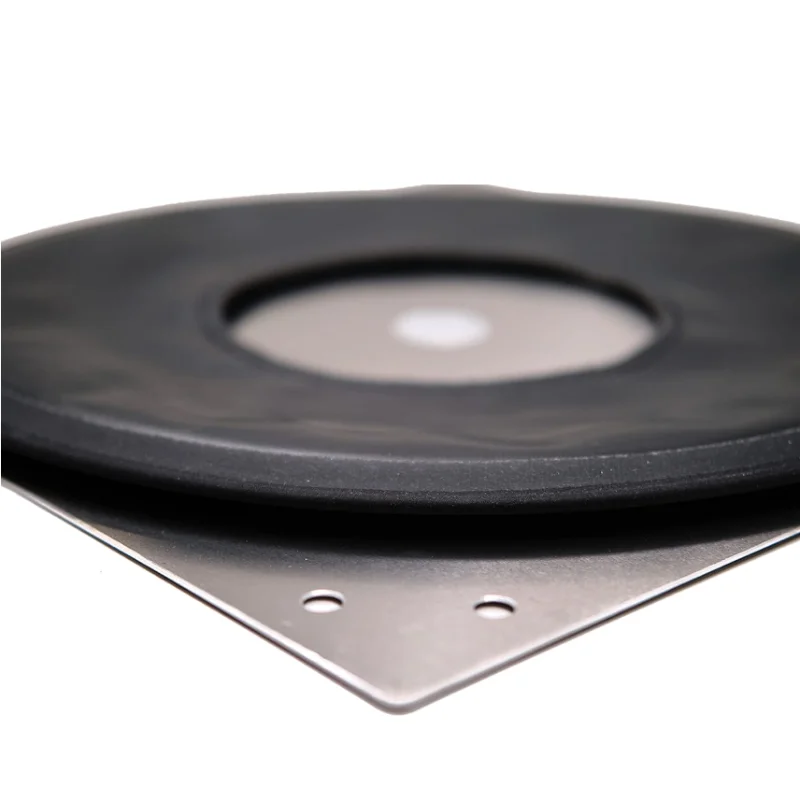

(4) Air Caster Load Modules: Core components that lift and move the load using a cushion of air.

-

(4) Interconnect Hoses with Fittings: Connect the load modules to the control console, ensuring synchronized operation.

-

(1) 4-Station Control Console with ON/OFF Ball-Valve: Allows the operator to control airflow to each module, facilitating precise maneuvering.

-

(1) 35’ Long Air Supply Hose with Fittings: Connects the system to the plant’s compressed air supply.

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity Operational Considerations :

Floor Requirements

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity requires smooth, non-porous surfaces to function effectively. Uneven or porous floors can disrupt the air cushion, leading to reduced performance. For floors that do not meet these criteria, consider using overlay materials such as sheet metal or heavy-duty plastic sheets to create a suitable surface.

Air Supply

Ensure that the plant’s compressed air system can deliver the required 196 SCFM at 60 PSI. It’s advisable to maintain an air supply capacity that is 30% higher than the minimum requirement to accommodate any unforeseen demands or inefficiencies.

Load Distribution

Proper load distribution is crucial for the safe and efficient operation of the air caster system. Ensure that the load is evenly distributed across all modules and does not exceed the individual bearing capacities.

Heavy Duty Air Caster Load Module System 360,000 LBS Capacity’s Advantages:

-

High Capacity: Capable of handling loads up to 64,000 lbs, making it suitable for heavy industrial applications.

-

Omnidirectional Movement: Allows for smooth and precise maneuvering in all directions, enhancing operational flexibility.

-

Reduced Floor Wear: The air cushion minimizes direct contact with the floor, reducing wear and maintenance costs.

-

Quick Setup: The system can be set up and operational within minutes, minimizing downtime.

-

Ergonomic Operation: Often, loads can be moved manually without the need for tow vehicles or winches, reducing operator strain.

Maintenance and Safety

-

Regular Inspections: Periodically check hoses, fittings, and modules for signs of wear or damage.

-

Air Quality: Ensure that the compressed air supply is clean and dry to prevent contamination and corrosion.

-

Training: Operators should be trained in the proper use and safety procedures associated with air caster systems.

Summary

Our Heavy Duty Air Caster Load Module System 360,000 LBS Capacity offer a robust solution for moving heavy loads with minimal effort and maximum precision. Their design emphasizes safety, efficiency, and versatility, making them an invaluable asset in various industrial settings.